The Change of the Baseball

Have you ever ripped open a baseball to find out what was inside? Or even went as far as unraveling the yarn to find the rubber or cork ball at the core? I did that a few times as a kid and actually hit the cover off one baseball with my wood bat. I remember finding Chinese comic strips wound up and put inside of it. It was a odd discovery and it led me to tear into a real baseball to find out what was inside. Did you know when baseball was first introduced, the home team had to supply baseballs, and players would make them at any size or shape for their advantage!

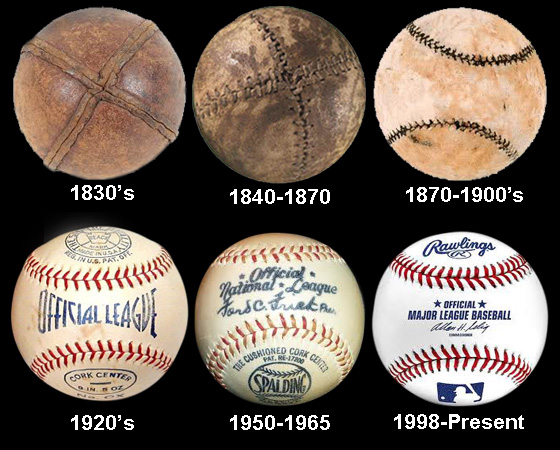

Baseball, America’s pastime was invented about 1839. Far from being organized and having set rules, baseballs had any type of solid substance for a core during the birth of baseball’s circular center piece. It could have been a rock, a walnut, anything laying around the farm. It was wrapped with string or yarn and it was stitched together with any type of leather available, mainly horsehide. Since there was not a baseball manufacturer at the time, teams were required to provide their own baseballs, so they made them to their own liking and design. This often gave them a advantage during play. Since players had to make the baseballs and were time consuming to make, they often only used one baseball per game. During the game the ball would turn dark brown from the use and tobacco spit on the ball, making it very hard to see. After the death of Ray Champman by getting struck in the head by a pitch, most likely not being able to see the ball during an evening game, the committees made strong efforts to replace baseballs when they got dirty.

In the 1850’s baseball began to get more organized. The first set measurements and materials used were from 5 1/2 oz to 6 1/4 oz in weight. They had decided that the core would be made out of India rubber which could weigh no more than an 1 oz. In the MLB today, a ball must weigh between 5 and 5 1/4 oz, and be made of rubber or cork. The circumference of the baseball must measure between 9 and 9.25 inches.

In 1858, H.P. Harwood and sons were the first company to commercially manufacture baseballs. Albert Spalding’s company took over baseball manufacturing in 1878 and produced baseballs for the National League. Spalding patented the cushioned wood core (the cork) in the late 19th century. During World War II they had to change from cork to rubber centers from golf balls, because there were restrictions on domestic materials during the war. In 1977 the MLB then switched to Rawlings Baseball’s and are still using them today. The MLB go through around 600,000 baseballs every year. The average ball lasts about 7-10 pitches. Today’s balls are considered to be “juiced” compared to the dead ball era (prior to 1920). It is thought that a tighter wound baseball makes the ball fly farther and come off the bat faster. Did you know that there can be a mile of yarn inside a Baseball? The MLB denies that the baseball balls have been made to travel farther off the bats, there has been no evidence to prove tampering with baseballs either.

The last big change to the baseball was in 1974, when the MLB changed the leather covering from horsehide leather to cowhide. Baseballs also go through vigorous testing. They are shot out of a air cannon at a northern white ash wall and must rebound no more than 0.578 percent of its original speed. Today’s baseballs have four layers of wool and poly/cotton string that circle around the cork in the center. The first layer is what the call four-ply gray yarn. They use this due to it’s ability to return to it’s original shape after hit a numerous amount of times. The second layer is three-ply white yarn, third is three-ply gray yarn, and the final layer is white poly/cotton yarn. Lastly the white Number One Grade cowhide over the top, 108 stitches of red waxed thread. Every ball is still hand stitched, it takes roughly 13 minutes to stitch every baseball. Once they are finished they go through a variety of stress tests and if they pass they are stamped with an “Official Baseball Of The MLB” and commissioner’s signature of that year, then shipped for game use. It was pretty neat to see the evolution of the baseball, I do not see the baseball being changed any time in the near future. If you ever find a ratty old baseball take a look inside, you may be surprised on what you find!

Trivia Question: What is the highest priced signed baseball in history?

– Matt Ingle

i have a ball, which resembles the pictured example circa 1830 in that the stitch is the same, the material appears to be the same, even in color it resembles your example

however it differs it that the stitched pattern is not the figure 8 as pictured but that of the 1870 ball

it is slightly larger than the modern era ball and a little bit smaller than a modern softball can you help me with some background and the transition from figure 8 stitch and perhaps comment on the the 1830 variant in your example and the possibility of the ball i have being a 1870 version rom the same club same as the only difference is in the pattern any information on your eamled 1830s ball in the example might give be a better starting point any information o knowledge o what i might have would be appreciated

robert owens

nevada texas

Howdie, I also have a 1930s baseball described by Robert Owen. and close to the 1930s baseball shown here. However my ball has only one seam with extra stitching. I classify my ball as a 1930s baseball after seeing your 1930s baseball.